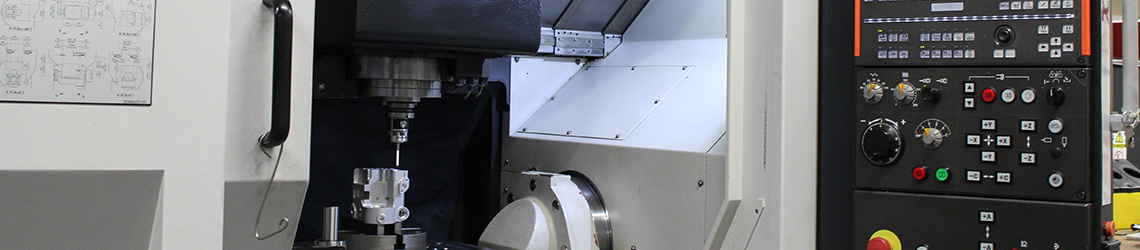

Production

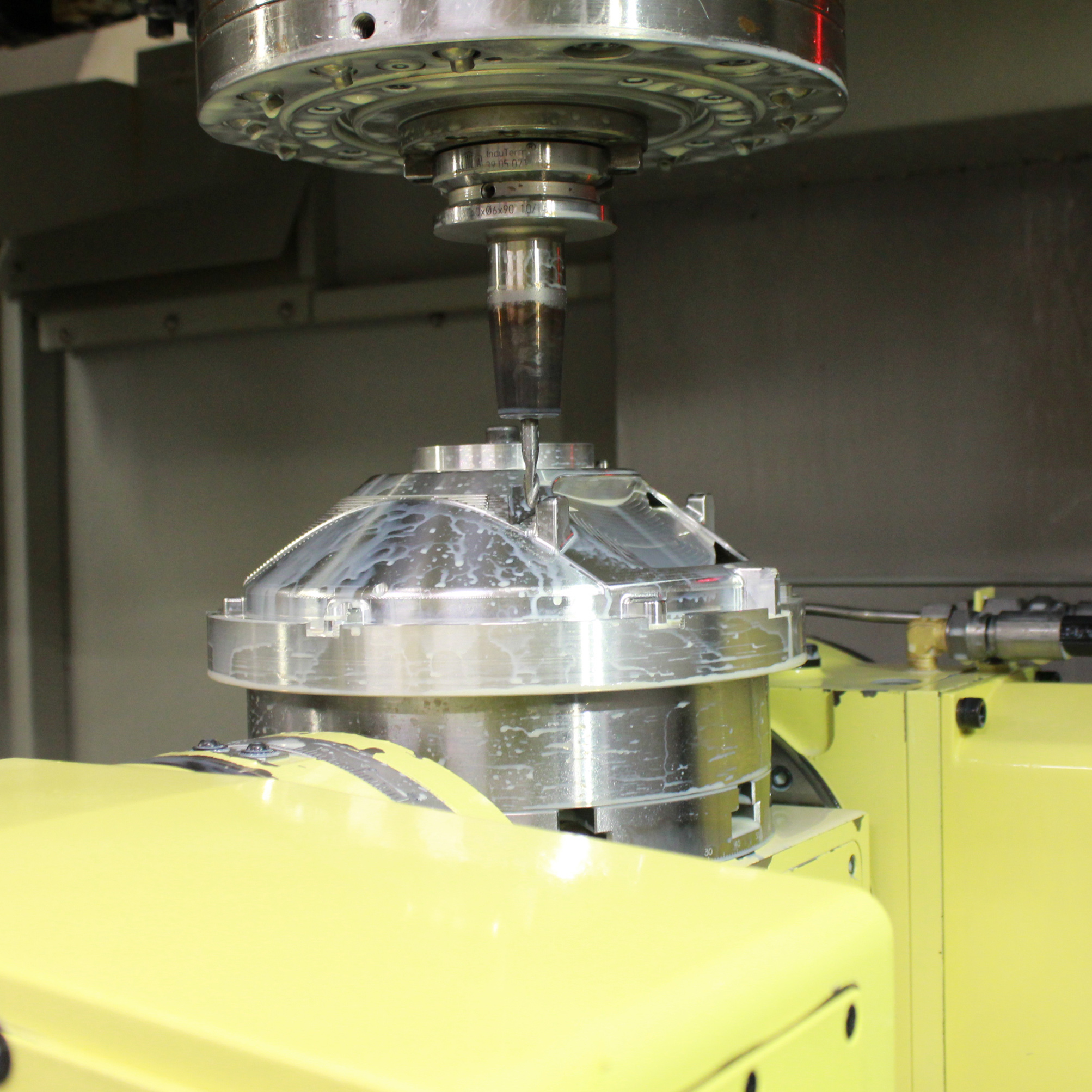

At Whiteley Brooks Engineering, our expert production engineers are able to fulfil our customer’s demands with precision and efficiency. By keeping our skills and machines up to date, we can be sure that these demands are met with the very latest in technology.

Drawing on this experience, we can, when required, work with our customers in the early stages of design concerning the choice of materials and feasibility of machining methods etc

We are familiar with most materials including steels, titanium, aluminium alloys, polymers and carbon fibres. We also have considerable experience in the finish machining of Additive Manufactured Parts (Three Dimensional Printing) and have worked with several companies working in this area. Two, Three, Four and Five Axis machining can be undertaken utilising our CAD-CAM systems and all of our machine tools are linked via our DNC 500 link to our server. This means that Part Programs can be both uploaded and downloaded from the machine tool.

Services supplied by Whiteley Brooks Engineering include:

- Two and three axis CNC turning

- Universal and cylindrical grinding

- Three, Four and Five Axis CNC milling

- Centre lathe turning

- Surface grinding

- Milling and drilling

Our facilities at Whiteley Brooks have recently expanded to include a third factory unit. This increases our capacity, allowing us to take on new projects. As part of our manufacturing processes, we can handle Wiring, E.D.M Spark Erosion and subsequent Plating’s and Heat Treatments.

CNC Milling and Turning Machines

-

- 5 Doosan DNM 5700 with 5th axis capability

- 9 Bridgeports with 4th axis capability

- 10 Hardinge Bridgeport with 5th axis capability

- 6 Hardinge Bridgeport with 4th axis capabilty

- 1 Mazak Variaxis 5 Axis Machining Centre

- 3 Kia CNC Lathes (Maximum Diameter 380mm)

- 2 Doosan CNC Lathes (Maximum Diameter 360mm)

- 3 Doosan Puma 2600 CNC Lathe (Maximum Diameter 480mm)

- 1 Doosan Lynx 220 CNC Lathe (Maximum Diameter 270mm)

- 1 Doosan Lynx 300 CNC Lathe (Maximum Diameter 400mm)

- 1 Doosan GT2100 CNC Lathe (Maximum Diameter 390mm)

- 1 Doosan Puma GT 2100M Lathe (Maximum Diameter 360mm with Live Tooling)

- 1 Doosan Puma GT 2600 Lathe

Conventional Machinery

- 5 Centre Lathes

- Pollard 4 Spindle Drill Press

- Jones and Shipman 1300 Universal Grinding Machine

- Jones and Shipman 540 Surface Grinder

- Snow Tub Grinder

- Speedhone Hone

- 2 Vibro Engraving Machines (ProPen)

- 1 Laser Marking Machine (Technifor)

- 2 Forklift trucks

- 2 KELCH i-tec Heat Shrink

- 1 Kasto Band Saw

- 1 Vertical Band Saw

- 1 Pedrazzoli Circular Saw

Inspection Equipment Includes:

- 3 Axis Manual Coordinate Measuring Machines

- 2 x 3 Axis CNC Coordinate Measuring Machines with Renishaw Modus CAD Software, allowing our quality engineers to work from customer solid models

- 5 Axis CNC Coordinate Measuring Machines with Renishaw Modus CAD Software, allowing our quality engineers to work from customer solid models

- 2.5M, Quantum M, 8 Axis Faro Arm running on Polyworks software

- Mitutoyo Shadowgraph

- Full Range of Micrometers and Verniers

- Granite Surface Plates

- Microscope and Measuring Software

- Full Range of Gauges and General Measuring Equipment

- Venda 365 gauging unit

- Starrett 400 series shadowgraph

Wiring

- Agie Charmilles Cut 20P Wire eroder

- Agie Charmilles Cut E 600 Wire eroder